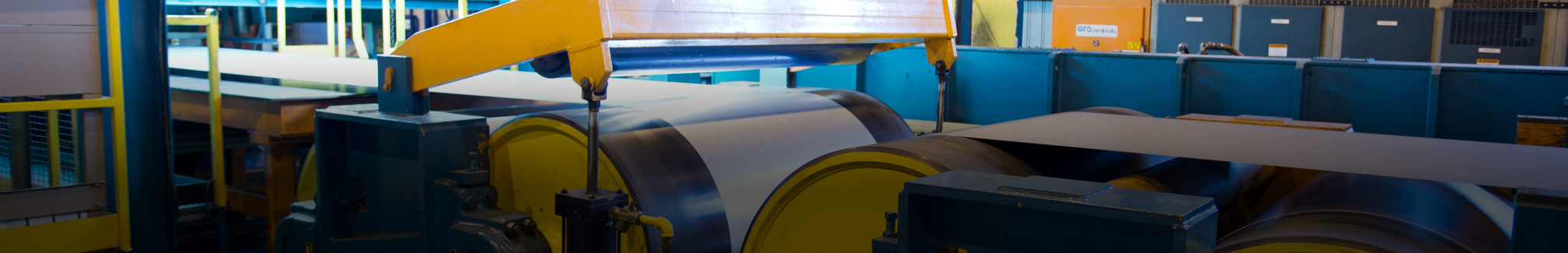

Taylor Steel has two Herr Voss tension level lines with wash and dry capabilities corporately that produce coils with remarkable shape and accurate sizing.

The Tension Leveling Line is comprised of an uncoiler, flattener, stitcher, drag bridle assembly, spread leveler, pull bridle assembly and recoil mandrel. The stretching is done by utilizing uncoiler brake-back tension, drag tension in the initial set of four bridle rolls, roll mesh in the leveler, pull tension in the second set of four bridle rolls and recoiler horsepower. The integration of these settings is determined by the gauge, width, material hardness and severity of the shape being corrected.

A wash unit, as part of the line, removes dirt and oil from the incoming strip reducing the chances of slippage, leading to greater control during the leveling process.

The Wash Unit is 35 feet long and has a pass line roll at the entrance, two 3M squeegee rolls for removing water from the strip surface and a pass line roll at the exit. As the strip passes through the wash section the top and bottom surfaces are sprayed with hot, soapy water almost 400 pressure nozzles. The water temperature (145 degrees) and pressure combined with the volume of water and soap solution removes the oil from both sides of the strip. The removal of the oil is done to facilitate tracking on the bridle rolls and optimize shape correction. Effective shape correction at maximum line speed requires that the surface of both the material and the bridle rolls be clean and dry.

The product produced has a flatness measured in the lowest of l-units, ready for fast, efficient, fault free processing. Material: Cold Rolled, Zinc Coated, Painted Steel in Commercial and High Strength Grades, Aluminum and Tinmill products.

Thickness/Width:

- .015"min to .100"max at 72" wide

- .005"min to .020"max at 48" wide (21" min.)